Filtr sprężonego powietrza na platformy poza

$414.221-19 Piece/Pieces

$393.51≥20Piece/Pieces

| Rodzaj płatności: | T/T,L/C |

| Incoterm: | FOB,EXW,CIF,CFR |

| transport: | Ocean,Land,Air,Express |

| Porta: | Shenzhen,Ningnbo,Qingdao |

Ms. YUKA Filtration

Co mogę dla ciebie zrobić?

$414.221-19 Piece/Pieces

$393.51≥20Piece/Pieces

| Rodzaj płatności: | T/T,L/C |

| Incoterm: | FOB,EXW,CIF,CFR |

| transport: | Ocean,Land,Air,Express |

| Porta: | Shenzhen,Ningnbo,Qingdao |

Model No: YD220

Początek: Chiny

Element Służy życiem: 6000 ~ 8000 godzin

Clapboard: Bez clapboard

Numer Filtra: 1

Materiał średni: Włókno szklane

Rodzaj: Filtr nabojowy

Materiał: Stop aluminium

Obudowa Serwują Lige: 15 lat

Wydajność Filtracyjna: Od 5 μm do 0,01 μm

Maxi. Działać Nacisk: 1.0MPA

Działać Temperatura: 1,5 ~ 80ºC

Korozja Oporu: Wewnątrz i na zewnątrz

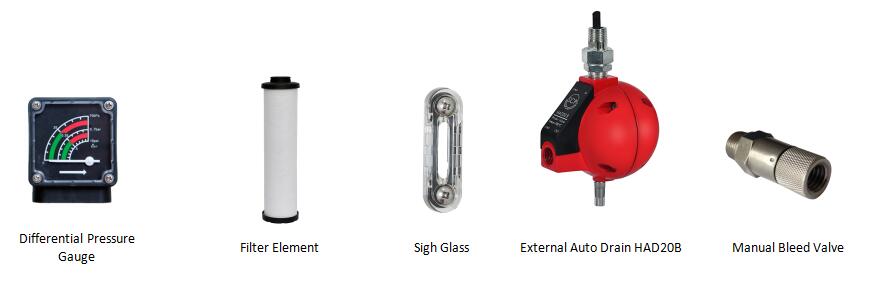

Części: Wskaźnik DP, automatyczne odpływ, szkło wzroku

Pakiet Transportowy: Brązowy wewnętrzny pudełko i karton

Klasa Filtracyjna: Średni filtr

Connection: Rc1-1/2"

Efektywność: F9

Projektowanie Płetw Dywersji Na Górnej Czapce: Mniejsza utrata ciśnienia

Usługa OEM I ODM: TAk

Flow Rate: 12.0m³/Min

Spadek Ciśnienia: Około 0,25 bara

Zawór Krwawiący: Do dyspozycji

Specification: Dimension:162x151x 676mm

| Jednostki sprzedaży | : | Piece/Pieces |

| Typ pakietu | : | Pakiet kartonu |

| Przykład obrazu | : |

|

The file is encrypted. Please fill in the following information to continue accessing it

Głównym powodem zastosowania filtra sprężonego powietrza jest wyeliminowanie zanieczyszczenia i poprawa jakości powietrza przy rozsądnych kosztach.

Potrzebujesz więc sprężonego filtra powietrza, ale jak wybrać najbardziej na miejscu filtr sprężonego powietrza do swojej aplikacji?

Rzućmy okiem na różne rodzaje filtrów powietrza i pytania, które pomogą Ci wybrać prawidłowy filtr.

| ①Assess the requirements of your application. Different industry require different solution. | ②What type of filtration is needed? Coalecent filter material removes solid and liquied contaminants from gas streams. Particulate filter media removes solid from gas streams. Absorber media removes hydrocarbon vapors from gas streams. | |

| ③Any specific micron of filtration performance you required? | ④What are the working conditions of your application? Mainly criteria of consider : Flow, working pressure, temperature,pressure loss,material of structure (stainless steel, aluminum alloy, mild steel, carbon steel) | ⑤Filter flow rate from how much SCFM? Pressure drop should be less than **bar? For saving the cost and protect environment. |

| Commodity | Compressed air filter | |||||

| Series | YD | |||||

| Flow rate | 12m³/min | |||||

| Element grade | 5μm/1μm /0.01μm/0.001mg/m³ | |||||

| Working pressure | 143 psi g | |||||

| Working temperature | 1.5℃~80℃ | |||||

| Material | Aluminum Alloy | |||||

| Color of housing | Red | |||||

| Trade term | EXW & FOB SHENZHEN | |||||

| Package | Internal Box & External Carton | |||||

| Warranty | 15 years for filter housing, 4000-6000 hours under rated working conditions for filter element | |||||

Filtruj klasa elementu

| Filtration Grade |

|

|

|

|

|

|

|

| PF | AO | AA | AX | ACS | AR | AAR | |

| Particle removal (ISO12500-3) | 5μm | 1μm | 0.01μm | 0.01μm | - | 1μm | 0.01μm |

| Outlet oil aerosol concentration (ISO12500-1) | 5mg/m³ | 0.6mg/m³ | <0.01mg/m³ | <0.001mg/m³ | <0.004mg/m³ | - | - |

| Filtration performance of Particle (ISO12500-3) | - | 99.999+% | 99.999+% | 99.999+% | 99.999+% | 99.999+% | 99.999+% |

| Filtration performance of (ISO12500-1) | 50% | 80+% | 99.9+% | 99.99+% | - | - | - |

| Element spanlife | 6000 hours | 6000 hours | 6000 hours | 6000 hours | 2000-3000 hours | 4000-6000 hours | 4000-6000 hours |

| Precede with | Before refrigerated air dryer | after air dryer | after AO | after AA | before AX | after desiccant dryer | after AR |

| Model | Pipe size | Flow rates | Dimension (mm) | |||||||

| L/S | m³/min | scfm | W(Width) | D (Depth) | H (Height) | A | B | C(clearance for housing) | ||

| YD017 | RC1/2" | 16.7 | 1.0 | 35.3 | 89 | 79 | 246 | 40 | 186 | 118 |

| YD025 | RC3/4" | 25.0 | 1.5 | 53.0 | 89 | 79 | 246 | 40 | 186 | 118 |

| YD030 | RC1/2" | 30.0 | 1.8 | 63.6 | 89 | 79 | 280 | 40 | 220 | 158 |

| YD035 | RC3/4" | 33.3 | 2.0 | 70.6 | 89 | 79 | 280 | 40 | 220 | 158 |

| YD058 | RC3/4" | 46.7 | 2.8 | 98.9 | 120 | 110 | 377 | 55 | 276 | 195 |

| YD068 | RC1" | 60.0 | 3.6 | 127.1 | 120 | 110 | 377 | 55 | 276 | 195 |

| YD080 | RC1" | 80.0 | 4.8 | 169.5 | 120 | 110 | 477 | 55 | 377 | 290 |

| YD145 | RC1-1/2" | 120.0 | 7.2 | 254.2 | 120 | 110 | 477 | 55 | 377 | 290 |

| YD220 | RC2" | 200.0 | 12.0 | 423.7 | 162 | 151 | 676 | 64 | 566 | 480 |

| YD260 | RC2-1/2" | 233.3 | 14.0 | 494.4 | 162 | 151 | 676 | 64 | 566 | 480 |

| YD330 | RC2" | 267.2 | 16.0 | 564.8 | 162 | 151 | 984 | 64 | 875 | 780 |

| YD360 | RC2-1/2" | 317.3 | 19.0 | 670.7 | 162 | 151 | 984 | 64 | 875 | 780 |

| YD405 | RC2-1/2" | 367.4 | 22.0 | 776.6 | 200 | 189 | 757 | 78 | 634 | 560 |

| YD430 | RC3" | 467.6 | 28.0 | 988.4 | 200 | 189 | 757 | 78 | 634 | 560 |

| YD620 | RC3" | 620.0 | 37.2 | 1313.6 | 200 | 189 | 1012 | 78 | 889 | 780 |

| Technical requirements | Maximum operating pressure: 10 barg Maximum operating temperature: 80°C Minimum operating temperature:1.5°C | |||||||||

| Pressure | Barg | 1 | 2 | 3 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| Psig | 15 | 29 | 44 | 73 | 87 | 100 | 116 | 131 | 145 | 160 | 174 | 189 | 203 | 219 | 232 | |

| Correction factor | 0.38 | 0.53 | 0.65 | 0.85 | 0.93 | 1.00 | 1.07 | 1.13 | 1.19 | 1.23 | 1.31 | 1.36 | 1.41 | 1.46 | 1.51 | |

1.1 yt017-yt0.35

1,2 YD058-YD145

1,3 YD220-YD620

Przypadki sukcesu

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.